On-Demand 3D Printing Reduced Time to Market by an Entire Year

Desktop Metal's Bound Metal Deposition (BMD) technology was key to easy 3D printing adoption for Curio's food processing equipment. By incorporating 3D printed designs in high-quality 316L stainless steel, Curio machines are now increasing the quality and yield of the seafood processed by the company.

Elliði Hreinsson founded and built Curio into a top producer of processing machinery for the heading, filleting, and skinning of fish. The company, which uses a fleet of Desktop Metal and ETEC 3D printers to remain agile and innovative, was recently acquired by Marel, a global leader in the development and production of tools, complete solutions, software, and services for the food processing of chicken, meat, and fish.

3D printing has transformed the food equipment at Curio.

A nod to the strong Icelandic roots of the company and its founder, Curio machines were developed to the needs of each fish processing scenario. "What sets these machines apart is the company's closeness to the industry," Hreinsson said. "We know the fish, we know the environments, we know how to design to get the best result for the fish."

After the acquisition by Marel, Hreinsson remains with the company as advisor working toward the continuous development of fish processing machines to improve durability, utilization, and speed, as well as serving as a supplier for parts through his manufacturing company, Gullmolar.

Hreinsson used innovation and resourcefulness to design and build any parts not available to bring the best food processing products to market. "Those motors were made in-house," he points out on a tour of the Curio prototyping facility. With manufacturing capabilities including CNC lathes and mills, five axis machining, water cutting, robotic bending, and welding, Hreinsson is always looking for the most efficient process available to bring his designs into production.

Elliði Hreinsson shows off the newest Curio C-2034 filleting machine featuring over 100 metal parts 3D printed on the Desktop Metal Studio System.

He has been excited about the possibilities of additive manufacturing since his first exposure in the 1990s when a friend purchased a gypsum 3D printer for casting molds -- he admits the designs were rudimentary, but the possibilities seemed endless. He incorporated additive manufacturing into prototyping operations in 2010 when he purchased his first FDM-style plastic 3D printers. "There was a new tool in my toolbox, new opportunities," he said.

However, to truly incorporate the benefits of additive manufacturing for the production of Curio machines, the company needed to be able to 3D print metal, specifically stainless-steel parts. "I was always looking at laser powder bed fusion printers," Hreinsson said. "I went to see some in action, but they were always terribly expensive and the part needed a lot of post-processing afterwards, so I didn't actually see the benefits."

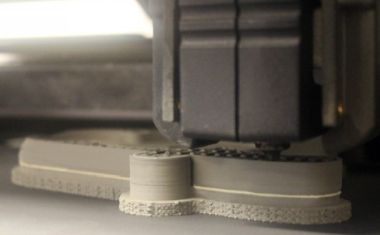

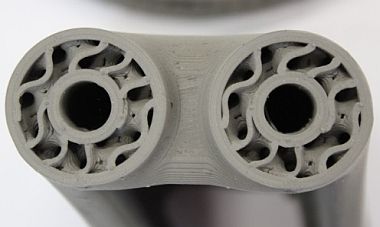

Build prep software provided with the Studio System 2.0 can automatically add a fully closed-cell infill for lightweighting of up to 50% with faster post processing times compared to solid 3D printed parts. Above, a Studio System build in process and, below, a cut-away section of the infill of 3D printed stainless steel.

After discovering Bound Metal Deposition technology from Desktop Metal, Hreinsson was convinced he'd found the key to unlocking new potential from his products. Unlike laser-based systems that melt loose metal powder with strict facility requirements, the Studio System extrudes bound metal rods for easy-to-adopt 3D printing that enables office friendly metal additive manufacturing. He invested in two Studio System 3D printers to produce 316L stainless-steel applications and a Desktop Metal Furnace to sinter the builds, producing dense metal parts.

With experience in a range of traditional CNC processes, Hreinsson admitted to increasing the thicknesses of his initial prints beyond the design guidelines because metal 3D printing was unknown and hard to trust. "I was skeptical of the strength of the material at first. But with more experience I realized we were increasing wall thickness for no reason -- just increased material and sintering time," he said, laughing.

The two-step process of the Studio System and Desktop Metal Furnace, just print and sinter, yielded immediate benefits for the innovation of Curio machines.

3D printed green parts await sintering at Gullmolar's production facility.

After realizing the quick-turn capabilities to produce and iterate parts on- demand, two additional Studio Systems and a second furnace were added to Gullmolar's production facility. Hreinsson also added digital light processing (DLP) machines from ETEC, Desktop Metal's brand of polymer 3D printers. With the ability to produce plastic prototype and metal parts for both testing and production, all six Desktop Metal systems (two ETEC Envision One machines and four Desktop Metal Studio Systems) run around the clock 3D printing parts.

3D Printing Drives Efficient Product Optimization

Fish processing machines are complex mechanical assemblies consisting of hundreds of small plates, gears, levers, and more. As in much of the food processing industry, these stainless-steel components are exposed to heat, water, and harsh cleaning chemicals with the expectation that they remain easy to sanitize, durable, and corrosion-free.

316L is an ideal food grade stainless-steel alloy that can withstand heat with a high resistance to acids, alkalis, and chlorides, such as salt, as well as a pitting resistance allowing for a surface that's easy to clean and maintain. Hreinsson knew offering high-quality stainless-steel material was a requirement for the adoption of 3D printed parts into production, and with 316L qualified on the Studio System, he was able to print innovative parts on-demand to improve performance.

"Zero-type" parts, left, are 3D printed in plastic on ETEC digital light processing machines to test for fit and function. Designs are quickly advanced to functional protoypes. The green part, center, is 3D printed in metal with ceramic interface for sintering to support the printed threads. The 316L stainless steel end-use part, right, in finalized within weeks, compared to 54-58 weeks for traditional production.

Curio machines are designed to be cleaned after every shift to maintain essential levels of sanitization. To ease this process, Hreinsson points to parts like a 3D printed latch he developed that detaches to allow the entire machine to split in half, making cleaning and maintenance easier.

The ease of customizing the design of each component allows for continuous iterations that improve the user experience of the product as it is tested and used in the production environment. If the skin of a specific species of fish gets stuck in the machine, he can easily print a bracket at a slightly different angle that optimizes the performance without the wait or cost of new tooling for a lost wax casting or CNC setup. By incorporating 3D printed designs, Curio machines are also increasing the quality of the seafood products they process.

Offering the Market Custom Solutions, Faster

In-house 3D printing helped Curio reduce machine development cycles by an entire year. With ETEC DLP machines, Hreinsson is able to print durable plastic parts with fast turnarounds to get prototype parts. These first mockups are critical to test that all connections are accounted for and all clearances are correct, yet getting a mold or waiting for a milling setup for these first prototype parts was expensive.

VIDEO: Metal 3D Printed Parts from the Desktop Metal Studio System

"We can create 'zero-type' parts without waiting for tooling and we're not married to the design," Hreinsson stressed. He can quickly advance designs from his plastic to his metal 3D printers to get to first-model prototypes with metal parts within a few weeks. And with his metal 3D printing capacity, production parts are available as soon as a design is finalized.

Directly 3D printing metal parts without long lead times allows improved designs to get to market faster. Above, a green state 3D printed motor mount. After sintering, the part is removed from the setter via the ceramic interface layer and ready for installation on the latest Curio filleting machine, below.

First lot parts for assembly of a new machine previously required 54-58 weeks as files were sent to Asia for tooling design to make molds to cast the metal parts. Producing on an island nation, 3D printing provided Curio the ability to source solutions locally. The cost savings and logistical efficiencies allow Hreinsson to produce more throughput with skilled labor locally cheaper than the long process of outsourcing abroad.

"Desktop Metal machines are speeding up development so much rather than waiting for CNC machining or mold making. We 3D print plastic parts to handle it, see the size and fit to get the correct form, and then we can directly print a stainless part. It's really difficult to be patient when you've made a new machine and need to wait a year to sell it. Now we are able to make the first lot of the machine with 3D printed parts without any dead time, we can push machines into the market as soon as we are ready."

The New Normal for Processing Machine Production

Existing Curio machines have had replacement wear parts as well as optimized designs 3D printed, but the newest filleting machine, the Curio C-2034, is the first model designed after Hreinsson invested in metal 3D printing with the Studio System. With over one hundred production 3D printed parts, from roller flanges and conveyor joints to mounting brackets, housings, and swivel arms, Hreinsson has difficulty remembering which components weren’t produced on the Studio System.

The Studio System 2 requires only an internet connection, ventilation and power, making it easy to quickly start printing metal parts.

With the latest iterations of Curio machines delivered to the market faster than ever, Hreinsson is excited about future possibilities with his metal 3D printing capabilities. He admits the design freedom and ability to prototype new ideas rapidly is an inventor's dream and he is looking forward to harnessing the power of 3D printing for continued performance improvement of Curio processing equipment. "I'm excited for the next project to develop because we have the printer now. When you start to develop a new machine and you have this in your toolbox, it's always in your head and the designs take off from there," he concluded.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy